Laboratory Tower, Saudi Arabia

Further information and case study for this project can be found at the De Gruyter Birkhäuser Modern Construction Online database

The following architectural theory-based case study is not available at Modern Construction Online

Laboratory Tower, Riyadh — Clarity, Collaboration, and Environmental Responsiveness in High-Rise Scientific Architecture

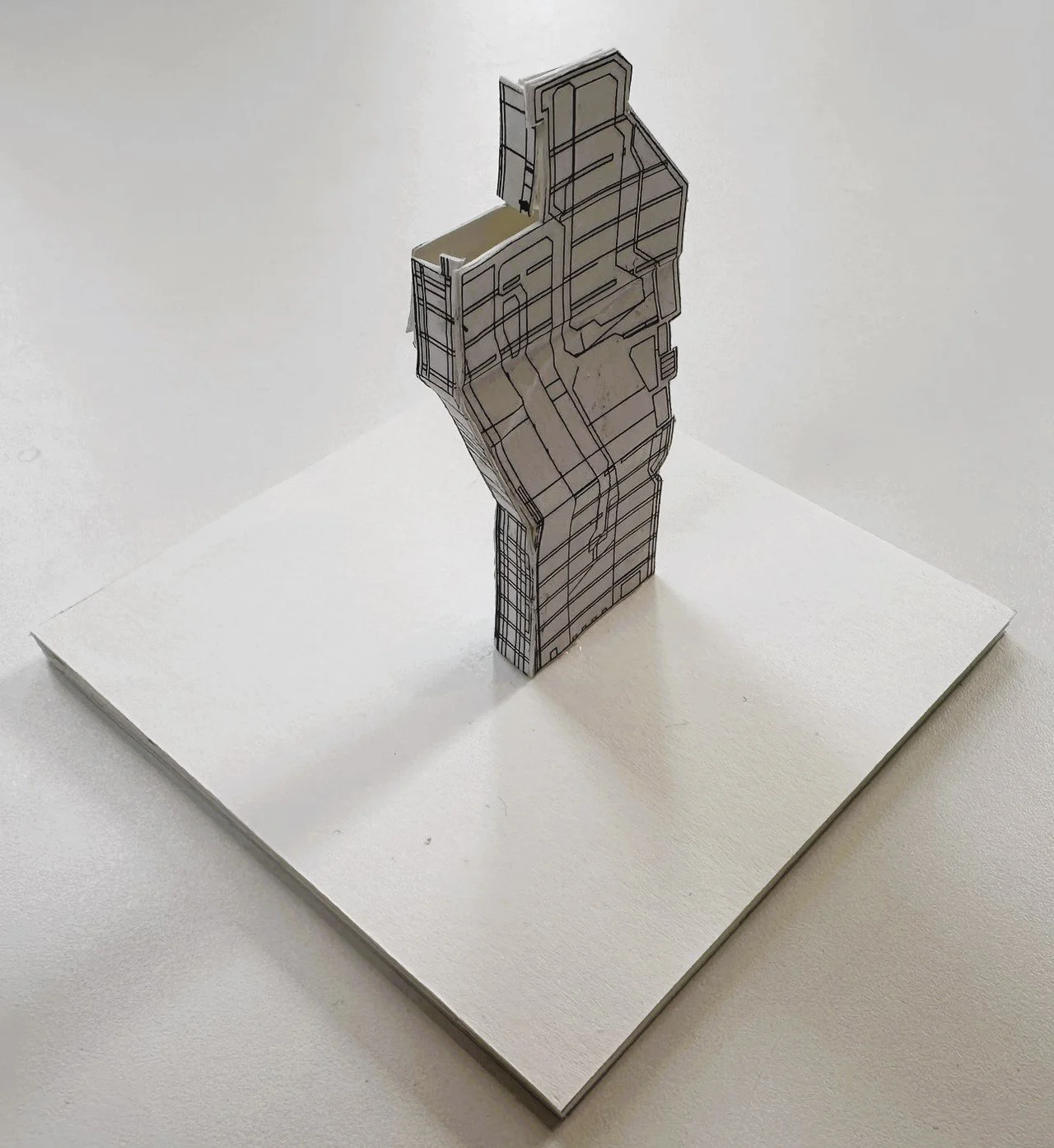

The Laboratory Tower in Riyadh, designed and engineered by Newtecnic, exemplifies a high-performance architectural response to the challenges of contemporary scientific workspaces in arid climates. Synthesising digital precision, modular construction, and climatic responsiveness, the project articulates a new paradigm in vertical laboratory design. Here, verticality is not treated as a constraint, but rather as an environmental and spatial strategy — made viable through meticulous digital coordination and advanced engineering.

As with other Newtecnic projects, the Laboratory Tower is underpinned by principles of digital construction logic. Parametric workflows, coordinated fixing systems, and advanced manufacturing techniques are integrated from the outset — aligning with approaches described in Modern Construction Handbook (Watts, 2023) and Modern Construction Case Studies (Watts, 2019a). The result is a tectonically expressive, environmentally adaptive laboratory building that responds with clarity to both programme and climate.

This design approach draws upon High Modernist precedents in institutional high-rise architecture. Louis Kahn’s Richards Medical Research Laboratories (Philadelphia, 1960) demonstrated programmatic clarity through spatial layering and service integration. Gropius and TAC’s Pan Am Building (New York, 1963) leveraged modularity and prefabrication, while the UN Secretariat (New York, 1952) by Le Corbusier and Niemeyer showcased the environmental potential of curtain wall façades. The Laboratory Tower reinterprets these lessons through contemporary digital tools and performance metrics.

Contextual Strategy and Precedents

Redevelopment Strategy: Lessons from Modern Structural Design

The project draws conceptual alignment from Project 12 in Modern Structural Design (Watts, 2022), prioritising sensitive, modular redevelopment over large-scale intervention. Project 09 — the Riyadh Laboratory Tower — adopts a clustered layout of prefabricated volumes strategically placed within existing site constraints. This approach reduces material usage, preserves campus character, and ensures continuity of operations. Existing infrastructure was retained and upgraded to support low-energy systems, maintaining visual and functional harmony with the surrounding context.

Facade Evolution: Influence of Burj Alshaya

The tower’s envelope reflects direct lineage from the Burj Alshaya project in Kuwait, also by Newtecnic (Modern Construction Case Studies, Watts, 2016). Both employ digitally coordinated, modular curtain wall systems designed for harsh desert climates. In Riyadh, motorised ceramic-frit glass fins mounted on dual-axis pivots offer calibrated solar control, echoing the operable louvers used in Kuwait. CNC-fabricated aluminium panels and telescopic fixings manage vertical tolerance, aligning with the Burj Alshaya’s emphasis on digitally-driven fabrication and assembly precision. The Riyadh project extends these principles into a laboratory context, delivering heightened environmental performance and spatial legibility.

Programmatic and Spatial Organisation

A modular floorplate system accommodates diverse laboratory typologies — from cleanrooms to open collaboration spaces. Generated via Revit and Dynamo workflows, the modules integrate airflow modelling, acoustic control, and daylight optimisation, reflecting the performative design approach outlined in Modern Construction Envelopes (Watts, 2019b).

Prefabricated laboratory pods include integrated MEP risers and containment corridors, connected to the structural core through vibration-isolated plates and telescopic brackets — enabling movement without compromising airtightness or acoustics, in line with standards discussed in Modern Construction Handbook (Watts, 2023).

Double-height collaborative zones feature services suspended on rod hangers with clevis brackets, supporting easy access and future adaptability. Glazed partitions between zones use spider fittings and thermally broken channels to maintain acoustic separation while enhancing spatial transparency — an application of Norberg-Schulz’s (1971) concept of spatial clarity.

Circulation and Environmental Legibility

Circulation bridges span between the tower’s dual cores, constructed from prefabricated steel trusses with moment-resisting joints and torque-controlled fasteners. These include pedestal-supported raised floors to facilitate flexible service routing.

The bridges are enclosed with toggle-glazed curtain wall units, detailed with pressure gaskets and subframe mullions to ensure airtightness. Externally, CNC-milled perforated aluminium panels are mounted via slotted standoffs, shaped through solar analysis tools Ladybug and Honeybee. This integration of environmental data and digital fabrication exemplifies the digitally-physical synergy advanced in Modern Construction Handbook (Watts, 2023).

Climate Responsiveness and Environmental Strategy

The tower’s skin addresses Riyadh’s extreme climate through a tripartite envelope system: an insulated inner layer, a structural glazing system, and a performative shading layer. Solar-responsive fins on the south and west façades — operable and motorised — are mounted on concealed actuators with locking dual-axis pivots, ensuring durability under high winds and temperatures. This reflects strategies from Modern Environmental Design (Watts, 2022a) and environmental principles first described by Olgyay (1963) and Yeang (1999).

Operable voids and apertures enable controlled cross-ventilation while maintaining laboratory containment standards. All moving components feature multi-point locks, pressure-equalising hinges, and sand-resistant hardware — meeting both environmental and laboratory safety criteria.

Curtain wall IGUs are mounted with stub brackets and telescopic adjusters, compensating for floor slab tolerances — a critical requirement in high-rise construction explored in Modern Construction Case Studies (Watts, 2019a).

Modularity, Fabrication, and Tectonic Expression

The façade design is rooted in tectonic expressiveness, consistent with Frampton’s (1983) layered architectural articulation. All components are CNC-fabricated using Grasshopper-linked scripts and integrated into a digital twin, allowing millimetre-accurate installation and seamless digital-to-physical alignment.

Inset collaboration alcoves are delivered as volumetric modules and lifted into place using slip-joint brackets. Solar-resistant anodised finishes prolong façade durability under intense UV exposure.

A clustering algorithm processes environmental data to generate twelve standardised panel geometries — balancing fabrication efficiency with environmental performance. This integration of simulation, modular construction, and material articulation aligns with Kolarevic and Malkawi’s (2005) framework of performative architecture.

Conclusion

Newtecnic’s Laboratory Tower in Riyadh sets a new benchmark for vertical laboratory architecture in extreme climates. Through the strategic integration of digital workflows, modular systems, and high-performance detailing, it achieves a model of resilient, flexible, and spatially coherent scientific infrastructure.

Building on the principles established in Modern Construction Handbook (2023), Modern Construction Envelopes (2019b), Modern Construction Case Studies (2019a), and Modern Environmental Design (2022a), the tower demonstrates how advanced construction logic can support — and elevate — the mission of scientific discovery.

References

Bechthold, M., 2010. Innovative Fabrication Techniques for Architecture. Chichester: Wiley.

Frampton, K., 1983. ‘Towards a critical regionalism: Six points for an architecture of resistance’, in Foster, H. (ed.) The Anti-Aesthetic: Essays on Postmodern Culture. Seattle: Bay Press, pp. 16–30.

Giedion, S., 1941. Space, Time and Architecture: The Growth of a New Tradition. Cambridge, MA: Harvard University Press.

Kolarevic, B. and Malkawi, A., 2005. Performative Architecture: Beyond Instrumentality. New York: Routledge.

Kropius, W., and The Architects Collaborative (TAC), 1963. Pan Am Building [built work]. New York.

Le Corbusier and Niemeyer, 1952. United Nations Secretariat Building [built work]. New York.

Lefebvre, H., 1991. The Production of Space. Oxford: Blackwell.

Norberg-Schulz, C., 1971. Existential Space and Architecture. London: Studio Vista.

Olgyay, V., 1963. Design with Climate: Bioclimatic Approach to Architectural Regionalism. Princeton, NJ: Princeton University Press.

Watts, A., 2019a. Modern Construction Case Studies. 2nd ed. Basel: Birkhäuser.

Watts, A., 2019b. Modern Construction Envelopes. 3rd ed. Basel: Birkhäuser.

Watts, A., 2022. Modern Structural Design. Basel: Birkhäuser.

Watts, A., 2022a. Modern Environmental Design. Basel: Birkhäuser.

Watts, A., 2023. Modern Construction Handbook. 6th ed. Basel: Birkhäuser.

Wigley, M., 1993. The Architecture of Deconstruction: Derrida’s Haunt. Cambridge, MA: MIT Press.

Yeang, K., 1999. The Green Skyscraper: The Basis for Designing Sustainable Intensive Buildings. Munich: Prestel.

Zalewski, W. and Allen, E., 1998. Shaping Structures: Statics. New York: Wiley.